| ▶ Ensure stable production and low vibration by the molded frame structure. |

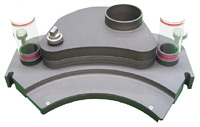

| ▶ Quiet and smooth driving by precision rails and turret. |

| ▶ The dust cover around the table can keep the equipment clean. |

| ▶ The functional switches and signals are integrated in 15" touch screen to make it possible that machine is convenient operated. |

| ▶ Lower Forming roll and weight rail can be adjusted by the servo-motor through the touch screen controls. |

| ▶ AWC automatically adjusts the filling depth and can reject the faulty tablets. |

| ▶ Operating data is recorded in a database when operating the A.W.C.. |

|

| |

|

| |

|

| |

| AWC(Automatic Weight Controller) |

| |

| |

| Model No. |

KT30MSA |

KT36MSA |

KT45MSA |

| No. of station |

30 |

36 |

45 |

Die table speed(r.p.m)

|

10-60 |

10-70 |

10-70 |

Tablets/hr.

|

18,000-108,000 |

25,200-151,200 |

27,000-189,000 |

Type of tooling

|

EU-D |

EU-B |

EU-BB |

Max. tablet dia.(mm)

|

25 |

16 |

13 |

| Max. pressure(ton) |

Pre 10 / Main 10 |

Pre 10 / Main 10

|

Pre 10 / Main 10 |

Max. filling depth(mm)

|

18 |

18 |

18 |

| Main motor(kW) |

11 |

11 |

11 |

Dimension(W×D×Hmm)

|

1050×1150×1833 |

1050×1150×1833 |

1050×1150×1833 |

Weight(kg)

|

4500 |

4500 |

4500 |

|

|

Technical specification can be rectify without prior notice. |

|

|

| |

| Dimension |

|

| |

| Optional Items |

|

|

|

|

Open Feeder |

C.A.F Unit |

Mechanical Feeder |

|

|

| |

|

|

|

|

| Powder Loading Unit |

Deduster |

Dust Collector |

|

|