| ▶ Mixing, kneading, granulating. |

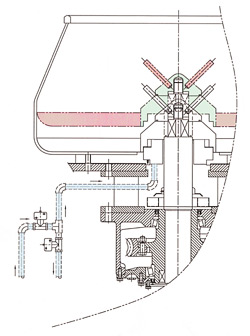

| ▶ Cone type vessel. |

| ▶ Inside of vessel became perfect cleaning is possible. |

| ▶ Open and close the exhaust damper device. |

| ▶ Special sealing system for shaft. |

| ▶ Convenient automatic open & close system for vessel cover. |

| ▶ Powerful driving by worm Gear. |

| ▶ Agitator Impellar is designed with the structure to maximize the buoyancy of raw material. |

| ▶ Chopper Impellar speed control at any rate it possible to have free forms of mesh. |

| ▶ Lid open/close by air cylinder(2 step). |

| ▶ Main Agitater Impellar lifting type for CIP. |

|

| |

|

| |

|

| |

Impellar Lifting

for Cleaning |

| |

|

|

|

|

|

| |

| Model |

KM120 |

KM240 |

KM450 |

KM650 |

KM840 |

KM1000 |

| Vessel full volume(ℓ) |

120 |

240 |

450 |

650 |

840 |

1000 |

Working capacity(ℓ)

|

50 |

100 |

200 |

300 |

400 |

500 |

| Agitator |

Motor(kW) |

7.5 |

11 |

15

|

22 |

30 |

37 |

| Speed(r.p.m) |

0 - 150 |

0 - 150 |

0 - 130 |

0 - 105 |

0 - 105 |

0 - 85 |

| Chopper |

Motor(kW) |

3.7 |

5.5 |

7.5 |

11 |

15 |

18.5 |

| Speed(r.p.m) |

0 - 3500 |

0 - 3500 |

0 - 3500

|

0 - 3500 |

0 - 3500 |

0 - 3500 |

| Dimension |

W(mm) |

1,600 |

1,700 |

2,000 |

2,150 |

2,800 |

2,850 |

| D(mm) |

900 |

1,000 |

1,200 |

1,400 |

1,450 |

1,600 |

| H(mm) |

1,800 |

1,960 |

2,300 |

2,650 |

2,720 |

2,880 |

|

|

|

|

|

|

|

|

|

|

Technical specification can be rectify without prior notice. |

|

|

| |

| Mixer for Pilot |

| |

|

| |

| ▶ The can be used for low volume production. |

| ▶ It can be mixed in the same recipe and production equipment. |

| ▶ Granular automatic exhaust is possible when exhaust into the air cylinder. |

| ▶ The air purge system is installed on the agitator and chopper impeller. |

|

| |

| Model |

KM10 |

KM60 |

| Vessel full volume(ℓ) |

10

|

60 |

Working capacity(ℓ)

|

5 |

30 |

Agitator

|

Motor(kW)

|

1.5

|

3.7 |

| Speed(r.p.m) |

0 ~ 350 |

0 ~ 350 |

| Chopper |

Motor(kW) |

0.4 |

1.5 |

| Speed(r.p.m) |

0 ~ 3,500 |

0 ~ 3,500 |

| Dimension |

W(mm)

|

830 |

1,050 |

| D(mm) |

500 |

650 |

| H(mm) |

1,200 |

1,300 |

| Weight(kg) |

|

400 |

1,000 |

|

|

|